Only experienced and properly instructed persons should handle Pharma Grade CO2 Gas under

pressure. Use only properly specified equipment which is suitable for Pharma Grade CO2,

its supply pressure and temperature. Refer to supplier’s handling instructions. The

substance must be handled in accordance with good industrial hygiene and safety

procedures. Protect containers from physical damage; do not drag, roll, slide or

drop. Do not remove or deface labels provided by the supplier for the

identification of the container contents. When moving containers, even for short

distances, use appropriate equipment eg. trolley, hand truck, fork truck etc.

Secure cylinders in an upright position at all times, close all valves when not in

use. Provide adequate ventilation. Suck back of water into the container must be

prevented. Do not allow backfeed into the container. Avoid suckback of water,

acid and alkalis. Keep container below 50°C in a well-ventilated place. Observe all

regulations and local requirements regarding storage of containers. When using

do not eat, drink or smoke. Store in accordance with

local/regional/national/international regulations. Never use direct flame or

electrical heating devices to raise the pressure of a container. Leave valve

protection caps in place until the container has been secured against either a wall

or bench or placed in a container stand and is ready for use. Damaged valves

should be reported immediately to the supplier Close container valve after each

use and when empty, even if still connected to equipment. Never attempt to

repair or modify container valves or safety relief devices. Replace valve outlet

caps or plugs and container caps where supplied as soon as container is

disconnected from equipment. Keep container valve outlets clean and free from

contaminates particularly oil and water. If user experiences any difficulty

operating container valve discontinue use and contact supplier. Never attempt to

transfer gases from one container to another. Container valve guards or caps

should be in place. Depressurisation of liquid CO2 below approximately 5 bar can

create solid CO2 which may block protective devices, pipework and create dry-ice

within containers. Containers, which contain or have contained flammable or

explosive substances, must not be inerted with liquid carbon dioxide.

Product name: Carbon dioxide (Pharma Grade CO2)

Trade name: Carbon Dioxide Food Grade, R744, Laserpure, CP Grade

Other Name: Carbon Dioxide (Special Gases)

Chemical name: Carbon dioxide

Chemical formula: CO2

INDEX No. –

CAS-No. 124-38-9

EC No. 204-696-9

REACH Registration No. Listed in Annex IV/V of Regulation (EC) No 1907/2006 (REACH),

exempted from registration.

Chemical name Carbon dioxide (Pharma Grade CO2)

INDEX No.: –

CAS-No.: 124-38-9

EC No.: 204-696-9

REACH Registration No.: Listed in Annex IV/V of Regulation (EC) No 1907/2006 (REACH), exempted from

registration.

Purity: 100%

The purity of the substance in this section is used for classification only, and does

not represent the actual purity of the substance as supplied, for which other

documentation should be consulted.

Trade name: Carbon Dioxide Food Grade, R744, Laserpure, CP Grade

Pharma Grade CO2 Specification

99.5% minimum

→ carbon monoxide ≤5 ppm

→ hydrogen sulphide ≤1 ppm

→ total NOx ≤2 ppm

→ sulphur dioxide ≤2 ppm

→ moisture ≤8 ppm

→ ammonia ≤25 ppm

The above concentrations are ideal volume fractions (= mole fractions). This product is manufactured under

conditions conforming to the requirements of the European Pharmacopoeia.

Pure gases are classified by grade: Pharma Grade CO2

The first digit of the grade classification indicates the ‘number of nines’ purity, e.g. N3.0 = 99.9% purity.

The second digit is the number following the last nine, e.g. N4.6 helium has a guaranteed minimum purity level of 99.996%.

| Grade | Minimum purity | Total impurities |

|---|---|---|

| N2.0 | 99% | 1% |

| N3.0 | 99.9% | 1000ppm |

| N4.0 | 99.99% | 100vpm |

| N5.0 | 99.999% | 10vpm |

| N6.0 | 99.9999% | 1vpm |

| N7.0 | 99.99999% | 100vpb |

Pharmaceutical Grade Carbon Dioxide (Pharma Grade CO2) gas cylinder.

CO <5ppm

H2S <1ppm

NOX <2ppm

SO2 <2ppm

H2O <8ppm

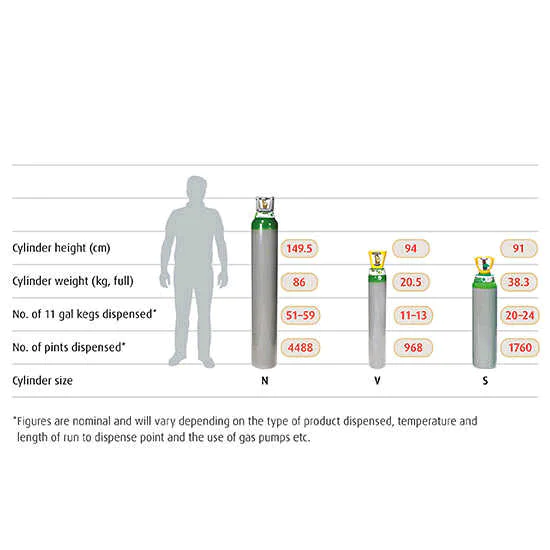

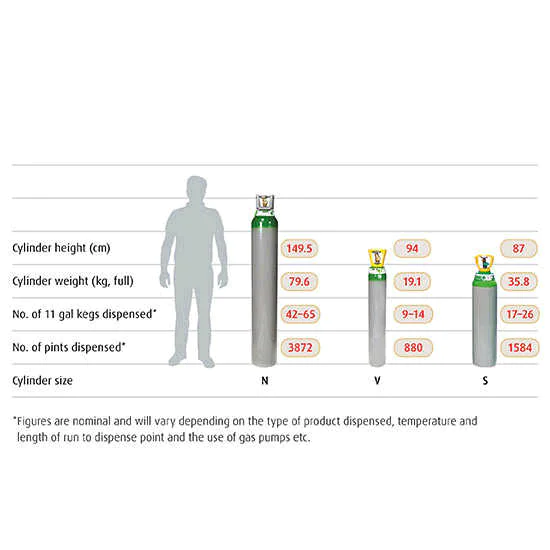

Please contact us for alternative cylinder sizes and certifications levels.

Be the first to review “Pharma Grade CO2 – Pharmaceutical Carbon Dioxide Cylinder” Cancel reply

Related products

Carbon Dioxide

Carbon Dioxide

Carbon Dioxide

Carbon Dioxide

Carbon Dioxide

Carbon Dioxide

Carbon Dioxide

Reviews

There are no reviews yet.